In the demanding world of manufacturing, the selection of plastic granules plays a crucial role in determining the quality, durability, and cost-effectiveness of the end products. Whether for automotive parts, packaging, or consumer goods, companies strive to find the perfect balance between performance and price. With the vast array of options available, from natural virgin HDPE granules to white milky LDPE granules, making the right choice requires thorough knowledge and understanding. Notably, partnering with a reputable Plastic Granules Manufacturer in India, or finding a reliable Granules Company in Ahmedabad, can significantly influence production outcomes, highlighting the importance of selecting high-quality plastic granules for business needs.

This article aims to guide businesses in making informed decisions when selecting plastic granules for their manufacturing requirements. It starts by discussing the importance of understanding your production needs, then delves into researching the different plastic granule options available, including granules in Dubai and other global markets. Further sections will cover ensuring quality and consistency in your plastic granules supply, the benefits of considering customization, and the importance of supplier support. By providing a comprehensive overview, this piece seeks to equip businesses with the knowledge needed to unlock the secrets to selecting the perfect plastic granules, ultimately aiding in the production of superior products.

Understanding Your Production Requirements

Identifying Product Needs

When selecting plastic granules for manufacturing, it is crucial for businesses to first clearly identify the specific needs of their products. This involves understanding the type of product being manufactured and its required properties, such as strength, flexibility, and color. For instance, industries like automotive or consumer electronics will require high-strength and durable plastics like ABS, whereas packaging might need more flexible materials such as polyethylene.

Assessing Desired Properties

The properties of plastic granules play a significant role in determining their suitability for various applications. Important properties to consider include melting point, viscosity, hardness, chemical resistance, UV resistance, and transparency. Each property impacts the performance and durability of the final product. For example, products exposed to outdoor environments would benefit from UV-resistant plastics to prevent degradation over time.

Considerations for Processing Techniques

Compatibility with existing manufacturing processes is another critical factor. The selected plastic granules must align with the processing techniques available at the production facility, such as injection molding, extrusion, or blow molding. This ensures that the manufacturing process can be carried out efficiently without causing defects or degradation of the material. Additionally, the environmental conditions at the production site, such as temperature and humidity, must be considered as they can affect the quality of the final product.

By thoroughly understanding these aspects, companies can make informed decisions that optimize the quality and efficiency of their manufacturing processes, ensuring that the final products meet the required standards and perform as expected in their intended applications.

Researching Plastic Granule Options

When embarking on the journey of selecting the right plastic granules for a business, understanding the diverse options available in the market is paramount. Plastic Granules India emphasizes the importance of thorough research to identify the plastic that best suits your production needs, ensuring quality, compatibility, and adherence to regulatory standards. This section delves into the types of plastics, their applications, material properties, and the significance of regulatory and environmental considerations.

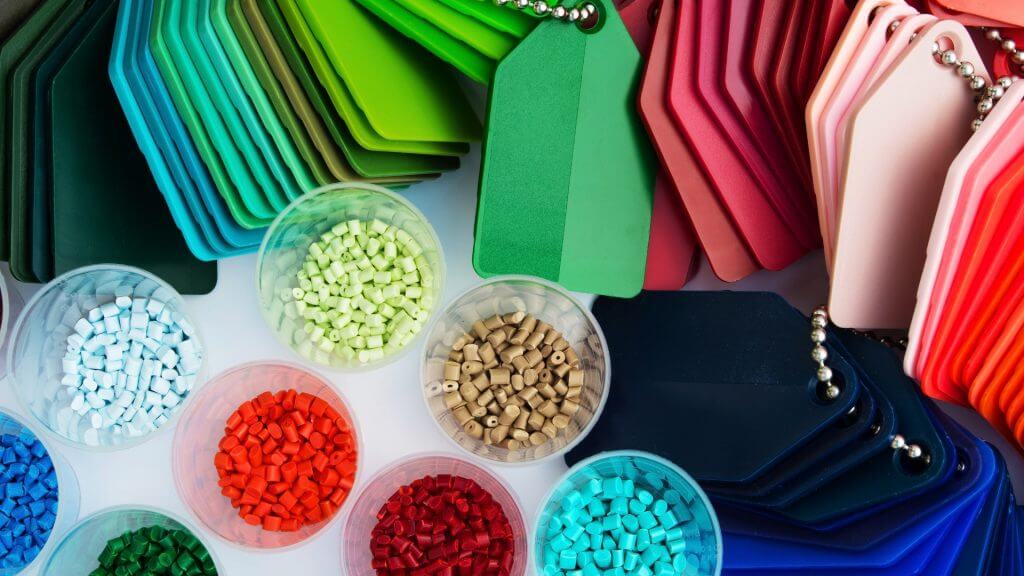

Types of Plastics and Their Applications

The world of plastics is vast, with each type offering unique properties suited for various applications. Polyethylene (PE) and polypropylene (PP) are among the most commonly used plastics, renowned for their versatility and wide range of uses. PE, for instance, is celebrated for its plasticity and is used in products like plastic bags, pipes, and food packaging. PP, known for its chemical and heat resistance, finds applications in food packaging, automotive parts, and medical equipment. Other plastics such as polycarbonate and polyvinyl chloride (PVC) are chosen for their specific attributes like impact resistance and flexibility, respectively, making them ideal for products like safety equipment and water pipes.

Material Properties and Compatibility

Selecting the appropriate plastic granules requires an understanding of their material properties and how they align with your manufacturing processes. The quality and purity of plastic granules are critical, as contaminants can affect the structural integrity and performance of the final product. Additionally, compatibility with processing equipment is essential to prevent operational inefficiencies and ensure high-quality output. For instance, the extrusion method, compounding techniques, and additives used in the production of plastic granules can significantly influence their properties. Businesses must consult with equipment manufacturers to confirm compatibility requirements, ensuring a smooth and efficient manufacturing process.

Regulatory and Environmental Considerations

In today’s environmentally conscious landscape, sustainability plays a crucial role in the selection of plastic granules. Companies are encouraged to opt for recyclable, biodegradable, or renewable materials to minimize environmental impact. This not only aligns with corporate social responsibility goals but also meets the increasing consumer demand for eco-friendly products. Furthermore, compliance with regulatory standards and certifications, particularly those related to food safety and environmental impact, is essential. Adhering to these regulations ensures the safety and legality of products while mitigating the risk of legal repercussions.

By carefully researching plastic granule options, considering material properties, and understanding regulatory and environmental implications, businesses can make informed decisions that optimize their production processes and contribute to sustainability efforts. Plastic Granules India stands ready to support businesses in navigating these choices, offering expertise and high-quality granules tailored to diverse manufacturing needs.

Ensuring Quality and Consistency

Importance of High-Quality Granules

Selecting high-quality plastic granules is crucial for maintaining the integrity and performance of the final products. Plastic Granules India emphasizes the use of granules that meet stringent industry standards such as ISO and ASTM to ensure consistent quality and performance. High-quality granules contribute significantly to the product’s durability and functionality, making it essential to choose suppliers who deliver granules with consistent properties.

Standards and Certifications

Adherence to recognized standards and certifications is a fundamental aspect of ensuring the quality of plastic granules. Suppliers should comply with quality standards that include tolerances for impact strength, stiffness, and resistance, which are critical for the granules’ application in various industries. Certifications such as ISO 9001 outline criteria for a quality management system, ensuring that the processes involved in plastic manufacturing meet customer requirements and enhance satisfaction.

Supplier Quality Assurance Practices

The commitment of suppliers to quality assurance practices is vital in the selection process. Plastic Granules India advises partnering with suppliers that have robust quality management systems in place. These systems should include quality assurance and quality control measures that are critical in preventing defects and ensuring the production of high-quality plastic granules. Suppliers should also have procedures for raw material inspection to prevent defects and ensure that the granules comply with the necessary safety and quality standards.

By focusing on these critical areas, businesses can ensure the quality and consistency of the plastic granules they procure, leading to improved product quality and customer satisfaction. Plastic Granules India stands ready to assist companies in sourcing the best quality granules that meet these rigorous standards.

Considering Customization and Supplier Support

Customization Options for Specific Needs

Plastic Granules India recognizes that different manufacturing applications may require specific types of plastic granules tailored to meet unique production specifications. Businesses should seek suppliers that offer customization options, such as custom colors, additives, or special formulations. This flexibility allows manufacturers to optimize their products’ performance by ensuring the plastic granules are perfectly suited to their needs.

The Role of Supplier Reliability

The reliability of a supplier plays a crucial role in the smooth operation of manufacturing processes. Companies should select suppliers known for their dependable delivery schedules and robust order fulfillment capabilities. A reliable supplier not only ensures the timely delivery of plastic granules but also significantly reduces the risk of production delays and potential financial losses. Furthermore, Plastic Granules India advises partnering with suppliers that maintain a stable supply chain, which is vital for continuous production without disruptions.

After-Sales Support and Its Importance

After-sales support is a critical factor that businesses must consider when choosing a plastic granules supplier. Effective after-sales services can include technical support, warranties, and responsive customer service to handle inquiries and resolve issues. Plastic Granules India emphasizes the importance of selecting suppliers that offer comprehensive after-sales services, which can lead to increased customer satisfaction and loyalty. These services ensure that businesses receive ongoing support, helping them maintain operational efficiency and product quality.

By prioritizing these aspects—customization options, supplier reliability, and robust after-sales support—companies can forge valuable partnerships with their suppliers. This strategic approach not only enhances the manufacturing process but also supports long-term business success in a competitive market.

Conclusion

Navigating through the intricate decisions surrounding the selection of plastic granules is pivotal for manufacturing businesses aiming to ensure the quality and efficiency of their products. The journey from understanding production requirements to assessing options, all while maintaining a keen eye on quality, customization, and supplier reliability, forms the foundation for selecting the perfect granules.

The article, courtesy of Plastic Granules India, has elucidated these crucial steps, highlighting how informed choices can significantly enhance product integrity and propel a business towards sustained success. By meticulously considering the types of granules, material properties, and the intrinsic role of supplier partnerships, companies can optimize their production processes to achieve remarkable outcomes.

In conclusion, the importance of selecting the right plastic granules cannot be overstated, given their impact on product performance and sustainability. As businesses strive to meet and exceed market expectations, the support and expertise of seasoned suppliers become invaluable. Plastic Granules India stands ready to accompany businesses on this critical journey, offering guidance, superior granule options, and comprehensive after-sales services to navigate the complexities of plastic selection.

For more tailored advice and to unlock the full benefits of quality plastic granules for your business, we encourage you to connect to our sales team for more information. This strategic partnership not only signifies a commitment to excellence but also ensures a future where quality, efficiency, and innovation converge to set new industry standards.

FAQs

What’s the Current and Future Demand for Plastic Granules?

The global market for recycled plastic granules was valued at approximately USD 3151.8 million in 2022. Forecasts suggest this market will grow to around USD 4182.50 million by 2030, with an annual growth rate of 3.60% from 2023 to 2030.

What Constitutes the Raw Material for Plastic Granules?

Plastic granules are primarily derived from thermoplastic polymers. These granules are produced by transforming the monomer propylene into a polymer through various methods. Due to their affordability, plastic granules are widely utilized across numerous industrial sectors.

Can You Explain the Process of Manufacturing Plastic Granules?

The manufacturing process begins with cleaning the plastic materials, which are then cut into smaller pieces using a cutting machine. These pieces are melted in an extruder to form granule lumps. Finally, the lumps are ground into granules of the desired size and packaged, typically in 50 kg batches.

How Are Virgin Plastic Granules Produced?

The production of virgin plastic granules starts with the insertion of raw materials (either crushed plastic wastes or resin) into the screw barrel of an extruder. Following multi-stage heating, these materials melt and are extruded through a mould. They then enter the feed cylinder of another extruder, where they undergo further heating in several stages.